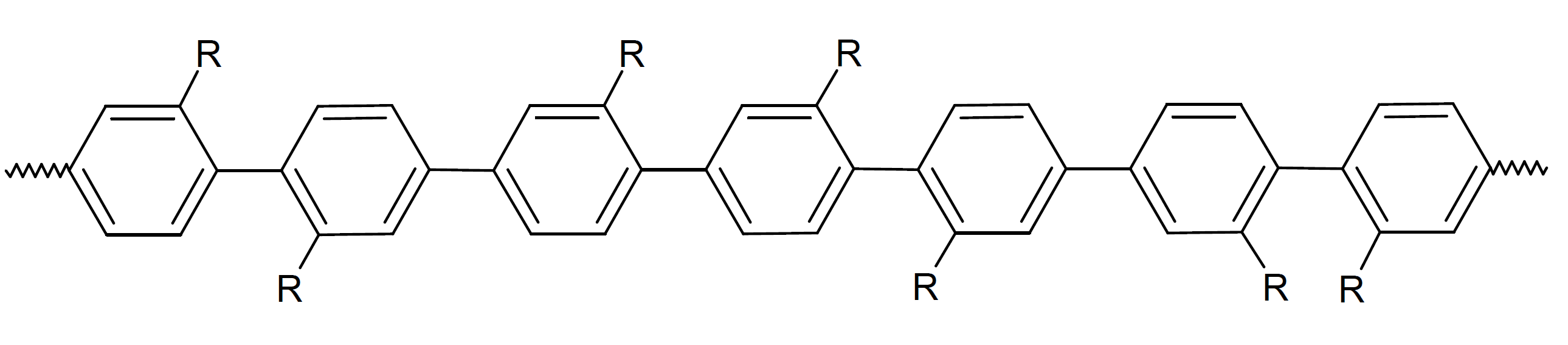

Poly-para-phenylene copolymer (PPP, SRP)

Properties

Poly-para-phenylene copolymer (PPP), also called self-reinforced polyphenylene (SRP), is one of the stiffest and strongest melt-processable engineering thermoplastics on the market. Due to its inherent rigid rod-like structure, it possesses outstanding mechanical properties over a wide temperature range including high strength and modulus and moderate high impact strength. It also possesses a high glass transition temperature (155°C) and a heat distortion temperature in the range of 150 - 160°C (300 - 325°F).1 Unlike most other high-performance thermoplasts, it has excellent mechanical properties at very low temperatures without fiber reinforcement. In addition, it possesses exceptional abrasion and solvent resistance, outstanding thermal-oxidative stability, and inherent flame resistance.

Important performance properties include:

- Very high mechanical strength and stiffness

- High compression strength and high pressure resistance

- Excellent resistance to wear and scratching

- Good cold temperature properties (stable to about -270°C1)

- High glass transition temperature of about 155°C

- Outstanding dimensional stability before and after processing

- Low thermal expansion coefficient (low thermal shrinkage)

- Outstanding acid and base resistance

- Good solvent and hot steam resistance (but lower than PEEK1)

- Good processability (can be extruded and injection molded)

For engineering applications, para-phenylene is typically copolymerized with other monomers or the phenyl rings have substituents chosen from a wide range of organic groups. Both greatly improves processability, e.g. the resins can easily be compression molded or extruded into complex part geometries.

Due to their high strength and outstanding wear and scratch resistance, SRPs can replace metal and other materials in many structural applications.

Commercial Self-reinforced Polyphenylene (SRP)

Commercial Self-reinforced Polyphenylene (SRP) resins are manufactured by Ensinger under the trade names TECAMAX SRP. They are often sold as neat resins or as semi-finished goods (rods, tubes etc.). The molded parts are very hard and stiff and can be machined and polished to tight tolerances with standard equipment using hardened metals or diamond tools.

Applications

Its exceptional mechanical, chemical, thermal and electrical properties make SRP an excellent choice for many very demanding

applications including semiconductor components, high performance bushings, bearings,

valves, valve seats, and aircraft substructures. Due to its high specific strength, SRP is an

excellent candidate for light-weight high-performance applications.

Electrical conductive polyphenylene (p- or n-doped) is used as an antistatic coating to protect integrated circuits from static charges, humidity, and corrosion.

Typical SRP engineering grades have a continuous service temperature in the range of 140 to 150°C (284 - 302°F).1

1Ensinger Tecamax SRP material data sheet, October 2005